Solving the Top Power Management Challenges

As demand for high-density AC/DC and DC/DC power architectures that use the minimum of components grows, so too do the challenges facing engineers tasked with their design. Here we consider some of the key power management design challenges and look at approaches that are being taken to address them.

Power Management Tools

Whether you are a dedicated power engineer or a system developer with power as one of a number of tasks, a key challenge of effective power management design is quickly identifying the best solution for a given application. This is where online tools can be particularly useful.

Take, for example, Silanna semiconductor’s Power Density Hero custom design tool, which simplifies and speeds the design, specification and prototyping of high-efficiency AC/DC and DC/DC power designs. This easy-to-use, fast and effective ‘all-in-one’ online tool is ideal for engineers looking to improve the efficiency and reduce the size and component count of a wide variety of power applications ranging from chargers and travel adaptors to industrial and appliance power.

Based around a simple and intuitive interface, the Power Density Hero design software allows registered engineers to enter a variety of key system parameters and performance requirements for their target DC/DC or AC/DC application. These include minimum and maximum input voltages, output types and voltage and controller IC types. When all of the information has been entered, the tool instantly calculates the necessary electronic components and values. Once this is done, Power Density Hero automatically sends a personalized, confidential document with comprehensive design specifications, circuit schematics and an optimized bill-of-materials (BOM) for all the devices, power ICs and additional discrete components needed for the design.

![Power-Hero-on-White[1]](https://powerdensity.com/wp-content/uploads/2020/11/Power-Hero-on-White1.png)

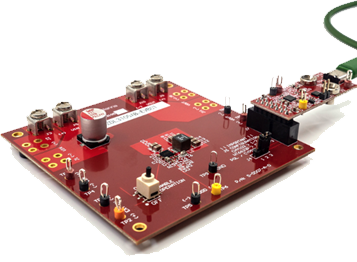

Silanna’s Power Density Hero custom design tool simplifies and speeds the design, specification and prototyping of high-efficiency AC/DC and DC/DC power designs.

[divilifeshortcode id=’4393440′]

Power Efficiency

ACF topologies differ from conventional flyback converters by re-using energy stored in the transformer’s leakage inductance that would traditionally be dissipated in a passive clamp snubber resistor.

[divilifeshortcode id=’4393448′]

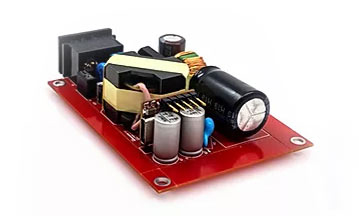

CO2 Smart Power™ includes ultra-compact, high-efficiency Active-Clamp Flyback AC/DC controllers and high-frequency PoL DC/DC converters that offer unrivalled efficiency and power density

[divilifeshortcode id=’4393450′]

Efficiency has reached the top of the power management design agenda as OEMs look to continually improve application performance while reducing overall power consumption. As well as dictating the system power needed to deliver appropriate operation, efficiency impacts many areas of power supply design from the need to remove reliability-impacting thermal emissions to the ability to reduce form factors by driving up power density.

Among the factors that impact power supply efficiency are the topology chosen, switching frequencies, conduction and switching losses in devices such as Power FETs, inductors and transformers, etc. and the number of components needed to build the supply.

In AC/DC power supplies, for example, choosing active clamp flyback (ACF) topologies can help to improve efficiency. ACF topologies differ from conventional flyback converters by re-using energy stored in the transformer’s leakage inductance that would traditionally be dissipated in a passive clamp snubber resistor. Supplying this ‘recycled’ energy to the load during the switching cycle improves converter efficiency. It also facilitates the use of a lower voltage rating synchronous rectifier switch on the secondary side, which reduces conduction losses.

For DC/DC point-of-load (PoL) converters, increasing operating frequency supports the use of smaller output filters that enhance efficiency by reducing losses.

Silanna has employed these approaches in its CO2 Smart Power™ family including ultra-compact, high-frequency PoL DC/DC converters that offer unrivalled efficiency and power density and the world’s first fully integrated active clamp flyback controllers, which can operate at efficiencies of up to 95%.

Power Density

High power density designs are essential in many applications, including fast chargers and power adapters where form factor and weight have a fundamental impact on user experience. Efficiency plays a key role in delivering high power densities, as do high levels of integration that reduce the BOM by minimizing components and board space.

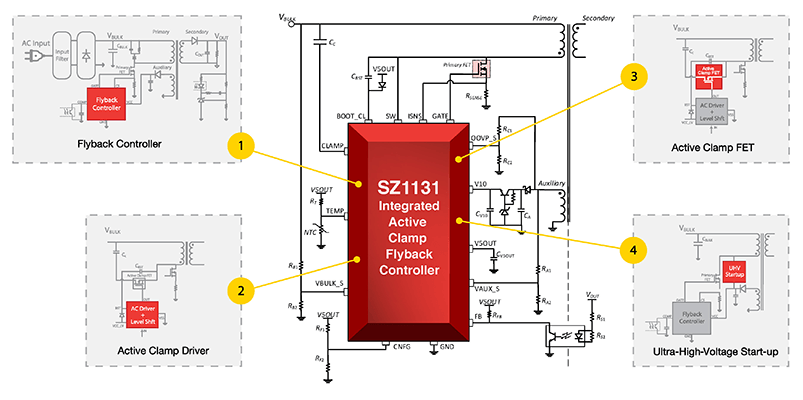

Silanna’s SZ11xx series of integrated ACF controllers, for example, combines into a single device an adaptive digital PWM controller and ultra-high-voltage circuits comprising active clamp driver, active clamp FET and start-up regulator. This unprecedented level of integration supports the rapid design of efficient, high-power-density AC/DC converters with low bill-of-material costs.

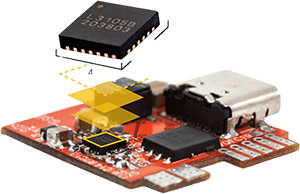

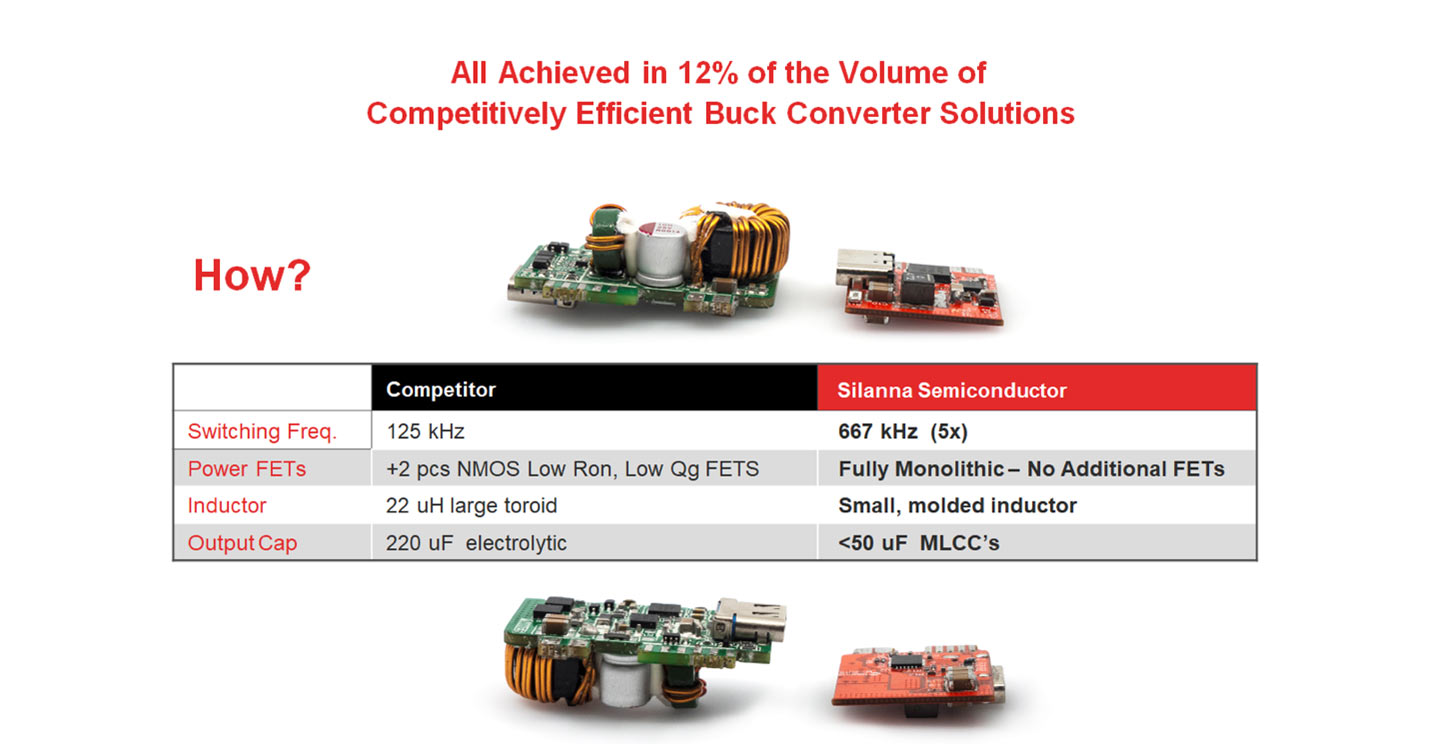

Or consider Silanna’s SZDL3105B fully-integrated DC/DC converter (buck regulator), which can supply up to 5A and 100W of output power. Despite the fact it accommodates industry-leading wide input and output ranges that support up to 27VDC input, it is supplied in a tiny QFN package measuring just 4 mm x 4 mm.

Silanna’s SZDL3105B fully-integrated DC/DC converter (buck regulator), which can supply up to 5A and 100W of output power.

[divilifeshortcode id=’4393460′]

Low BOM Cost

[divilifeshortcode id=’4393482′]

Delivering effective power management designs within tight budgets is always a challenge, not least when developing power solutions for cost-sensitive consumer applications. Despite this, looking to reduce the cost of individual components is not always the best way to deliver the best value-for-money. Often, more integrated solutions that help to minimize the overall bill-of-materials (BOM) by reducing the total component count a design requires is a much more effective way of keeping cost down.

Take, for example, Silanna Semiconductor’s CO2 Smart Power™ SZDL3105B, which is a fully integrated DC/DC converter in a QFN package measuring just 4mm x 4mm. This 100W, wide-voltage, high-frequency PoL converter reduces costs by eliminating the need for additional FETs and allows smaller, lower priced inductors and capacitors to be deployed.

The same is true of the AC/DC solutions in Silanna Semiconductor’s CO2 Smart Power portfolio such as the SZ1131 controller for adapters up to 120W. Featuring the industry’s highest level of integration, the SZ1131 incorporates an adaptive digital PWM controller, ultra-high-voltage (UHV) active clamp FET, active clamp gate driver and startup regulator to minimize the overall system cost.

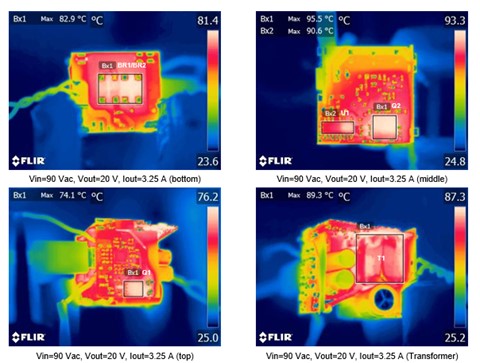

Thermal Management

Managing heat is another key area where high-density power supply designs require special attention. The thermal management challenges in such designs are becoming increasingly more difficult due to the small surface area available for dissipating the heat generated from the power conversions and maximum allowable safe operating temperatures. While power supplies are becoming smaller, their efficiencies need to be proportionally improved to avoid over-heating or exceeding the touch temperature of the case. The limiting factor for the thermal management comes from the worst-case power dissipation, which becomes wasted heat inside the case. For AC/DC power supplies this typically occurs when operating at full output power with the lowest line voltage (e.g. 90Vac). For DC/DC converters the highest conversion ratio between input and output voltages results in the worst-case power dissipation.

Silanna’s AC/DC and DC/DC chipsets offer best-in-class efficiencies to allow industry-leading power densities. The OptiMode™ digital controller maintains high efficiency across varying line, load and temperature operating conditions. This, in turn, not only makes the high-density power supply designs easier by minimizing the need for additional heat-sinks, thermal potting compound etc., but also reduces associated costs and weight.

EMI

Electromagnetic interference (EMI) is another key area of concerns for power supply designers. Both the conducted and radiated EMIs need to have sufficient margins against international regulatory requirements, such as CISPR22B/EN55022. While commonly used input and output EMI filter components, such as common mode choke, differential inductor, X and Y capacitors are used to meet sufficient EMI margins, they often add undeniable cost, complexity, and size penalties in power supply designs. Furthermore, customers often have additional requirements on these filtering components such as maximum capacitance values for Y-capacitor (limiting the leakage current). In general, EMI is a complex area for power supply designers and any mitigation techniques that can be incorporated in the device level, such as flyback controller, is highly appreciated by the designers and end-customers.

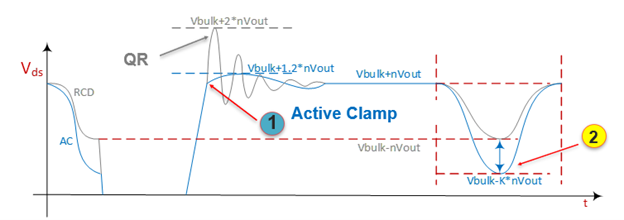

Silanna Semiconductor’s fully-integrated Active Clamp Flyback controllers provide significantly superior EMI performance compared to conventional QR flyback controllers due to several reasons.

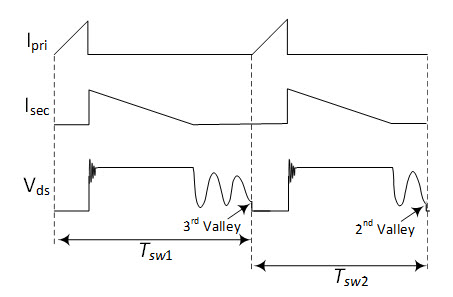

First, active clamp flyback operation eliminates the voltage spike at the turn-off event of the primary side FET (marked with point 1 in the following figure). This practically eliminates the EMI due to the ringing of the switching node voltage. Also, the soft-switching of the internal active-clamp FET does not introduce any additional EMI to the system. Furthermore, during the turn-on event of the primary side FET, the active clamp operation enables a near zero-voltage-switching (ZVS) of the primary FET by drastically reducing the QR valley (marked with point 2 in the following figure). This results in smaller switching voltage and hence, lower EMI.

Second, Silanna’s ACF controllers tightly regulate the range of operating switching frequencies regardless of line and load conditions. The OptiMode™ digital controller ensure the switching frequency of the system does not vary over a wide range, so that the input filter can be optimized for the limited range of the operating frequencies. This practically enables the power supply designers to select an input filter that maximizes the attenuation only in frequency range of interest, without the need for complex filter design and bulky reactive components.

Third, Silanna’s ACF controllers incorporate an advanced QR valley switching feature, where the number of QR valleys varies in consecutive switching cycles and effectively introduces a natural dither in the system, thereby reducing EMI. This effectively reduces EMI by 3 dB – 7 dB over the frequency range between 150 kHz – 500 kHz.

An example is shown in the following figure, where the controller changes the mode-of-operation from 3rd valley to 2nd valley in consecutive switching cycles. The switching scheme effectively achieves 2.5 valley switching when averaged over multiple switching periods.

The number of valleys is changed from cycle-to-cycle, ensuring no audible noise is generated during the advanced QR valley switching. The feature is disabled for switching frequencies less than 70 kHz for the same reason.

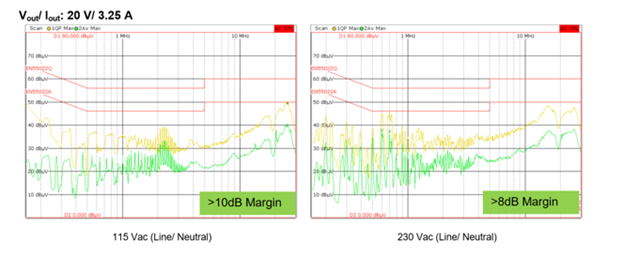

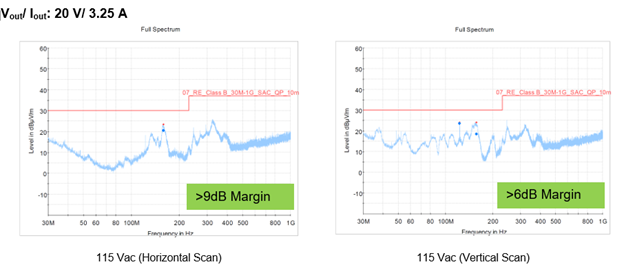

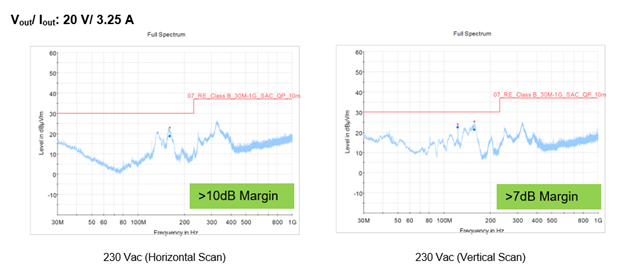

The following Conducted and Radiated EMI results show more than 6dB margin is achieved in a 65W USB-PD reference design (RD-29) with a single-stage input filter that uses a differential inductor only (no common mode choke).

Conducted EMI: 20V/3.25A (65W) measured at low line (left) and high line (right)

Radiated EMI: 20V/3.25A (65W) measured at low line (top) and high line (bottom)

Design Complexity

The complexity of power management applications can increase as engineers seek to deliver ever-higher power densities and meet ever-higher performance targets. However, this does not necessarily have to be the case. For example, in addition to the cost benefits mentioned earlier, the other advantage of reducing component count by choosing more integrated solutions is a significant reduction in design complexity.

Highly integrated DC/DC converters such as the SZDL3105B, for example, eliminate the need for specification and implementation of additional FETs and allow the use of smaller and easier-to-implement passive and magnetic components.

And the SZ1131 fully integrated AC/DC controller completely eliminates the need for engineers to design and implement separate FETs, drivers, and regulators. The result is a device that provides the ease-of-design of a simple flyback controller with all the benefits of an ACF design, including recycling of the leakage inductance energy of the flyback transformer and limiting the primary FET drain voltage spike during the turn-off events.

Discrete Power Device vs IC

In engineering there is often a ‘make versus buy’ decision, which will be dictated by a variety of factors including application specifications, available resources, time constraints, the ability to meet standards certifications and, naturally, budget. For the power engineer, that decision typically comes down to choosing whether to design a circuit using discrete components or ‘off-the-shelf’ ICs.

In the past designers had little choice but to assemble their power conversion and management architectures using discrete devices such as MOSFETs and diodes. While this approach allowed scope for optimization based on the components selected, there are a growing number of integrated ICs that minimize the requirements for discretes without compromising design specifications.

Take the example of active clamp flyback (ACF) designs that are replacing traditional flyback designs as engineers look to improve the specification and performance of their products while reducing size, weight and cost.

In addition to recycling energy that would previously have been dissipated as heat, ACF topologies can deliver additional benefits depending on the approach taken to implementation. Applying intelligent digital control to the clamp circuit, for example, allows near zero-voltage switching (ZVS) turn-on of the primary flyback FET and management of the turn-off drain voltage.

Until recently this type of adaptive, intelligent control has added circuit complexity and has not been straightforward to implement. Now, however, the advent of fully integrated ACF controllers is significantly simplifying the design of small, light and high-efficiency converters that require the minimum number of external components.

Time to Market

As companies look to focus engineering resources on core, application-specific competencies, there is a growing need for third-party design support to simplify the implementation of power management designs.

As well as the online tools mentioned earlier, this support extends to evaluation boards and reference designs that minimize the time needed for development and prototyping.

Silanna Semiconductor offers a variety of boards in support of its DC/DC converter technologies and full reference designs for applications such as fast chargers. These include an ACF-based GaN reference design that sets a new benchmark for fast charger power density, efficiency and no-load power.

Built around Silanna’s SZ1131 ACF controller and incorporating Transphorm’s Super GaN FET, the RD-29 is a production-ready 65W 1C USB-PD reference design that incorporates everything a designer needs to develop a charger and that already exceeds conducted and radiated EMI requirements by more than 6 dB. Our list of production ready reference designs using Silanna Semiconductor’s AC/DC and DC/DC ICs will continue to grow with more single-port and multi-port USB-PD reference designs targeting various power levels.

Speed of Power Management Design

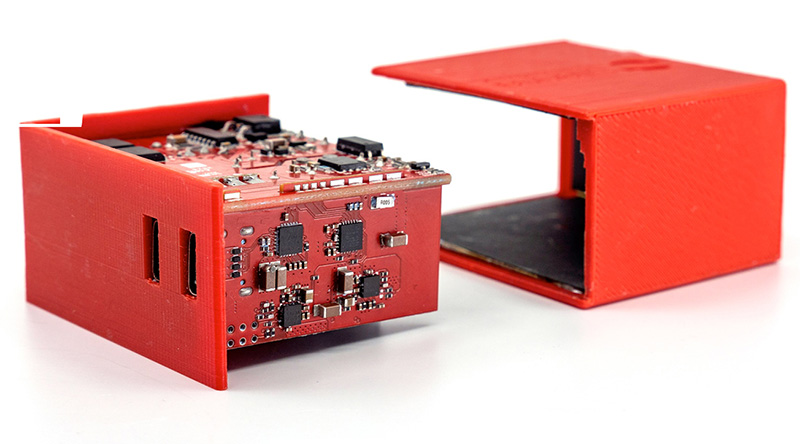

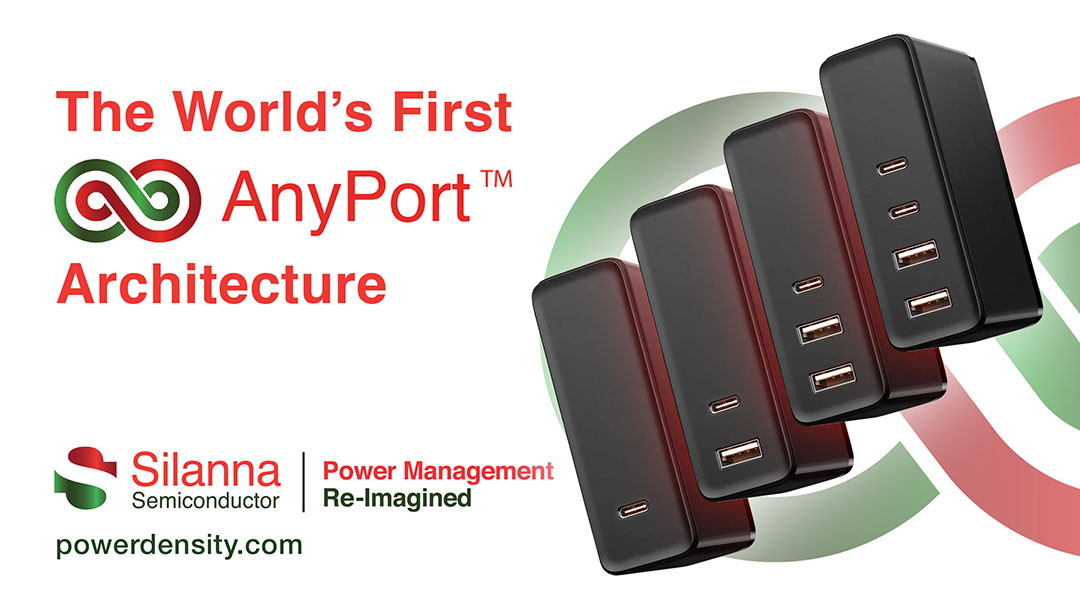

Bringing together the company’s CO2 Smart Power™ families of advanced ACF controllers and high-frequency DC/DC converters, the new AnyPort™ RD-5 delivers a high-power-density, ultra-efficient, production-ready solution for multi-port 65W USB-PD applications.

Representing the latest addition to Silanna’s growing family of silicon- and GaN-based fast charger reference designs, the RD-5 is an all-silicon solution that will simplify and speed charger development by providing everything an engineer needs to rapidly prototype and test a fully functional 65W 2C unit. The design, which combines Silanna’s SZ1130 fully-integrated AC/DC active clamp flyback (ACF) controller and two of the company’s SZPL3102 DC/DC converters, provides a cased power density of 11.4W/inch3 and operates with an end-to-end peak efficiency in excess of 91.5%. Efficiency is quite flat across the universal input voltage range (90 – 265Vac). Because the design exceeds conducted and radiated EMI requirements by more than 6dB it eliminates the need for pre-production validation and certification, speeding up the production cycle.

Power Management Design Support

Of course there are times when dedicated support will be required – and this is when engineers need to seek out qualified professionals who understand their applications and the best way to meet their design goals.

It was in order to satisfy these requirements that Silanna Semiconductor set up its Asian Center of Excellence (ACE) in 2020.

Based in the Philippines, the ACE is becoming an essential source for customer assistance, education, training, and information and allows Silanna to take a proactive and focused approach to regional customer technical support.